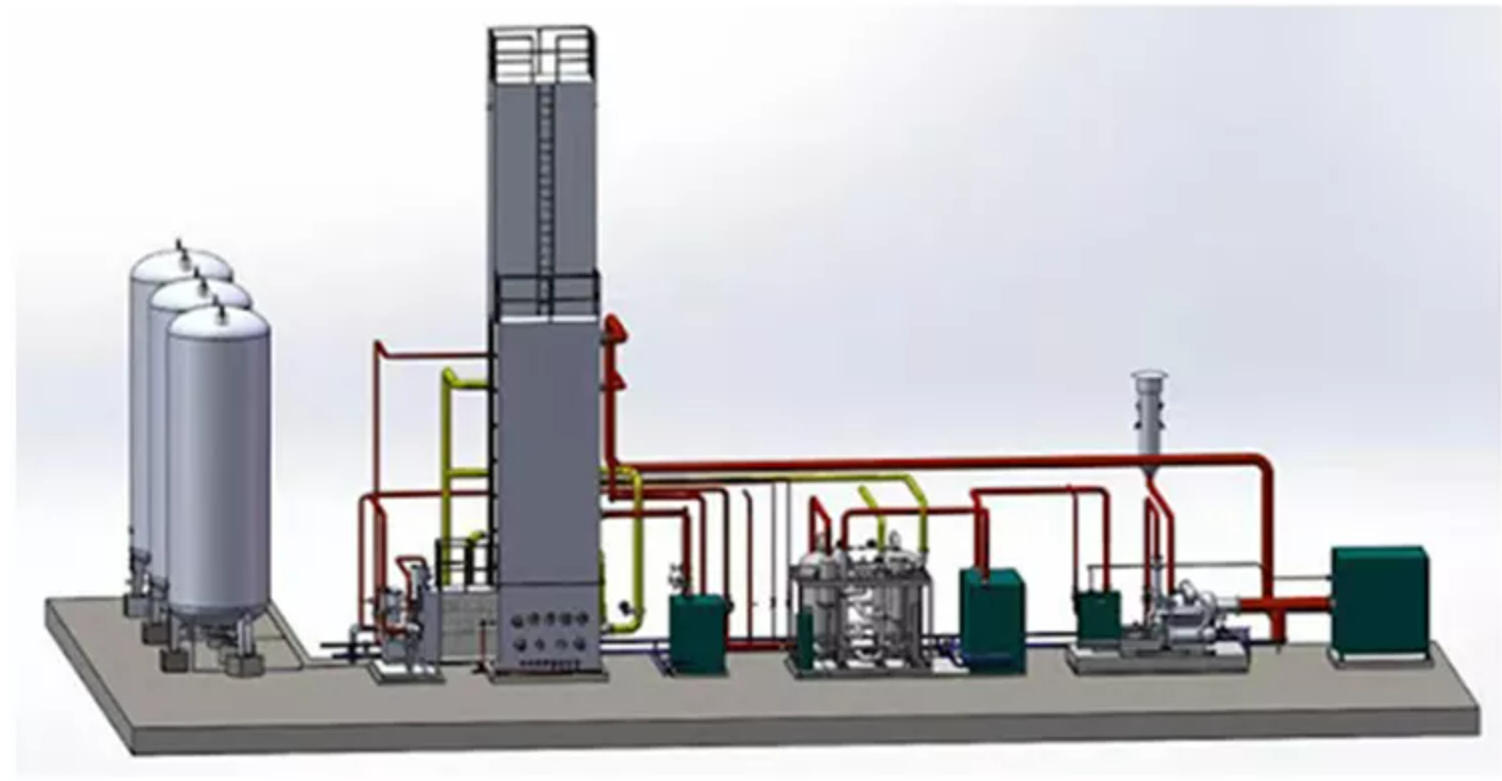

Find Professional Cryogenic LOX Separation Unit, Air Separation Unit Plant System, High-quality Low Temperature Oxygen Separate Unit on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

Work Principle

The basic principle of air separation plants is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen- enriched liquid air. The oxygen- enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen.

The upper tower is divided into two sections: with the liquid- air inlet as the boundary. the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

| Product Name | Cryogenic air separation plant | Oxygen Purity | ≥99.6% | |

| Production | 50Nm³/h—5000Nm³/h | Nitrogen Purity | ≥99.99% | |

| Brand | KunPeng | Model | KDONAR | |

| Main Part | Air compressor system, Pre-cooling System, Air Purification System, Fractionating Column System, Turbo Expander System, Filling System, Instrument and Electric Control System | |||

| Application Field | Medical & Industrial & Animal husbandry & Defense | |||

Product Categories : PSA Oxygen/Nitrogen Generator > Liquid Oxygen Plant